1. Precision

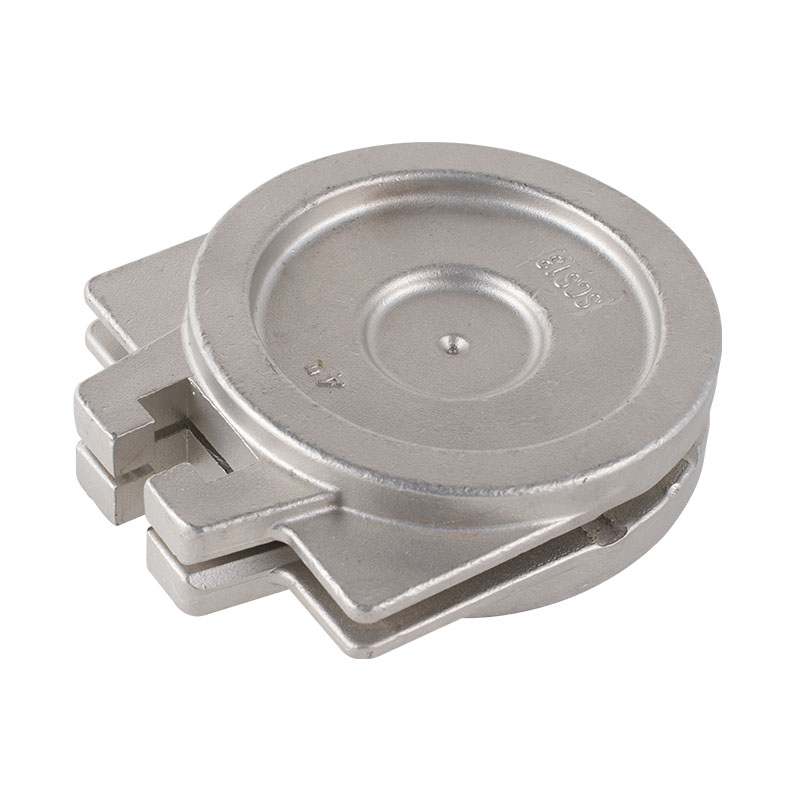

Lost Wax Investment Casting, also known as precision casting, is a manufacturing process that involves creating high-quality metal parts by pouring molten metal into a mold made from a wax pattern. This process allows for the creation of parts with intricate designs and tight tolerances, making it ideal for producing gate valve components. The key advantages of this process include:

High Dimensional Accuracy: Our gate valve parts are manufactured with exceptional precision, ensuring they fit nicely within the valve assembly.

Complex Geometries: The investment casting method allows us to produce highly detailed and complex valve components that other methods may struggle to achieve.

Smooth Surface Finish: The process results in a smooth surface, reducing the need for post-processing and enhancing the valve’s overall performance.

2. High-Quality Materials

The materials used in the production of Lost Wax Investment Casting Gate Valve Parts are carefully selected for their strength, durability, and resistance to corrosion. Common materials include:

Stainless Steel: Highly resistant to rust and corrosion, making it ideal for applications in harsh environments.

Carbon Steel: Known for its toughness and strength, it is nice for high-pressure applications.

Alloy Steel: Provides strength, wear resistance, and heat resistance, making it suitable for high-temperature conditions.

Bronze and Brass: Often used for parts requiring high wear resistance and good corrosion resistance, especially in marine or chemical applications.

These materials ensure that our gate valve parts can withstand extreme conditions, from high-pressure systems to corrosive environments, extending the lifespan of the valves and reducing maintenance costs.

3. Cost-Effective and Efficient Manufacturing Process

The Lost Wax Investment Casting process offers several advantages in terms of cost-effectiveness and manufacturing efficiency:

Lower Production Costs: Investment casting allows for the creation of complex parts without the need for expensive machining processes, reducing overall manufacturing costs.

Reduced Material Waste: The process is highly efficient, using minimal material and reducing waste, which makes it an environmentally friendly option.

Faster Production Lead Times: The precision of the casting process minimizes the need for additional machining, leading to shorter production cycles and faster delivery times.

By leveraging the efficiency of the investment casting process, we can deliver high-quality gate valve parts at competitive prices, ensuring our clients receive good value for their investment.

4. Quality Assurance and Testing

At every stage of the production process, we maintain rigorous quality control measures to ensure that our gate valve parts meet or exceed industry standards. Each part undergoes comprehensive testing, including:

Dimensional Inspection: To verify the precise measurements of each part.

Material Testing: To confirm that the material properties meet the required specifications.

Pressure and Leak Testing: To ensure the parts perform reliably under pressure and are leak-free.

This attention to detail guarantees that our clients receive parts that are not only functionally reliable but also safe to use in their gate valve systems.