Key Advantages

1. Robust Construction

One of the primary advantages of the Carbon Steel WCB Flanged Ball Valve Casting is its robust construction. Made from high-quality WCB material, these valves offer good mechanical strength, allowing them to withstand high pressure and temperature conditions. This durability is crucial for maintaining operational efficiency in demanding environments, where other materials might fail.

2. Corrosion Resistance

Although carbon steel is typically more susceptible to corrosion than stainless steel, the WCB Flanged Ball Valve can be treated with protective coatings or finishes. This mitigates the risk of rust and degradation, enhancing the valve's lifespan. For applications handling corrosive fluids, it is crucial to apply appropriate surface treatments to optimize performance.

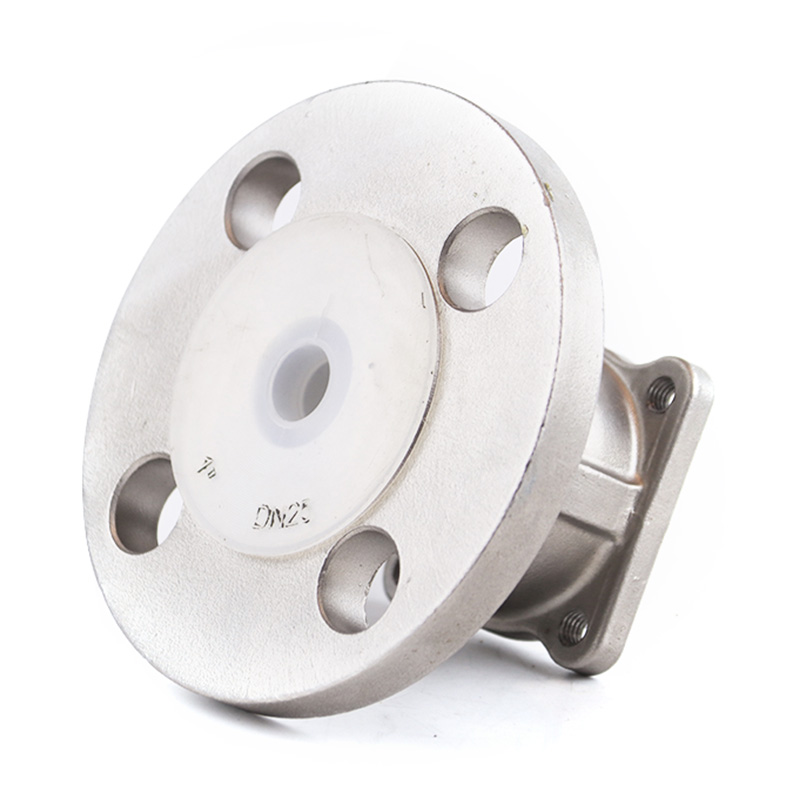

3. Flanged Connection

The flanged design of the Carbon Steel WCB Flanged Ball Valve Casting facilitates easy installation and dismantling. Flanged connections provide a secure fit that simplifies alignment with existing pipeline systems and allows for quick maintenance or replacement without extensive downtime. This design feature is particularly valuable in industries where regular valve upkeep is necessary.

4. Full-Bore Design

Many Carbon Steel WCB Flanged Ball Valve Castings feature a full-bore design, which allows for an unobstructed flow path. This configuration reduce pressure drops and enhances flow efficiency, making it suitable for applications requiring good flow rates. The ability to maintain high flow capacity while reduce turbulence is a significant advantage.

5. Reliable Sealing Performance

The Carbon Steel WCB Flanged Ball Valve Casting is engineered for reliable sealing performance. The precision-machined ball and seat ensure a tight seal when the valve is closed, effectively preventing leaks. This reliability is essential in applications where fluid contamination and safety are concerns.

Applications

1. Chemical Processing

In chemical plants, the Carbon Steel WCB Flanged Ball Valve Casting is often used to control the flow of aggressive chemicals. While it may require special coatings for corrosive substances, its robust construction and sealing capabilities ensure that fluid management remains safe and efficient.

2. Oil and Gas Industry

The oil and gas sector extensively utilizes Carbon Steel WCB Flanged Ball Valve Castings to manage the flow of crude oil, natural gas, and other hydrocarbons. The valve's ability to withstand high pressures and demanding conditions makes it good choice for pipeline systems in this industry.

3. Water Treatment

Water treatment facilities rely on the Carbon Steel WCB Flanged Ball Valve Casting to regulate the flow of water and chemicals in treatment processes. Its durability and dependable sealing prevent leaks, ensuring proper flow management in systems where maintaining water quality is critical.

4. Power Generation

In power generation plants, the Carbon Steel WCB Flanged Ball Valve Casting is crucial for controlling the flow of steam and water. Its ability to endure high temperatures and pressures while providing seamless operation is vital for maintaining efficiency and safety in energy production processes.

In conclusion,The Carbon Steel WCB Flanged Ball Valve Casting is an essential component in many industrial applications, thanks to its robust construction, reliable sealing performance, and versatility.