Durable Construction

The Working Pressure Ball Valve Casting is made from high-quality materials, often including stainless steel, carbon steel, or other alloys. This construction ensures that the valve can withstand high pressures and is resistant to wear and corrosion. The materials used in the Working Pressure Ball Valve Casting are chosen to cater to specific application needs, enhancing performance and longevity.

High-Performance Sealing

A significant advantage of the Working Pressure Ball Valve Casting is its effective sealing capabilities. It typically features a precision-engineered ball and seat that work together to create a tight seal when the valve is closed. This design minimizes leakage and ensures that fluids remain contained within the system, which is crucial for safety and efficiency in operational environments.

Versatile Operating Conditions

The Working Pressure Ball Valve Casting is designed to operate under a range of working conditions. It can handle various pressure levels and temperatures, making it suitable for different applications, whether in low-pressure systems or high-pressure environments. This versatility allows the Working Pressure Ball Valve Casting to be utilized in various industries without compromising its performance.

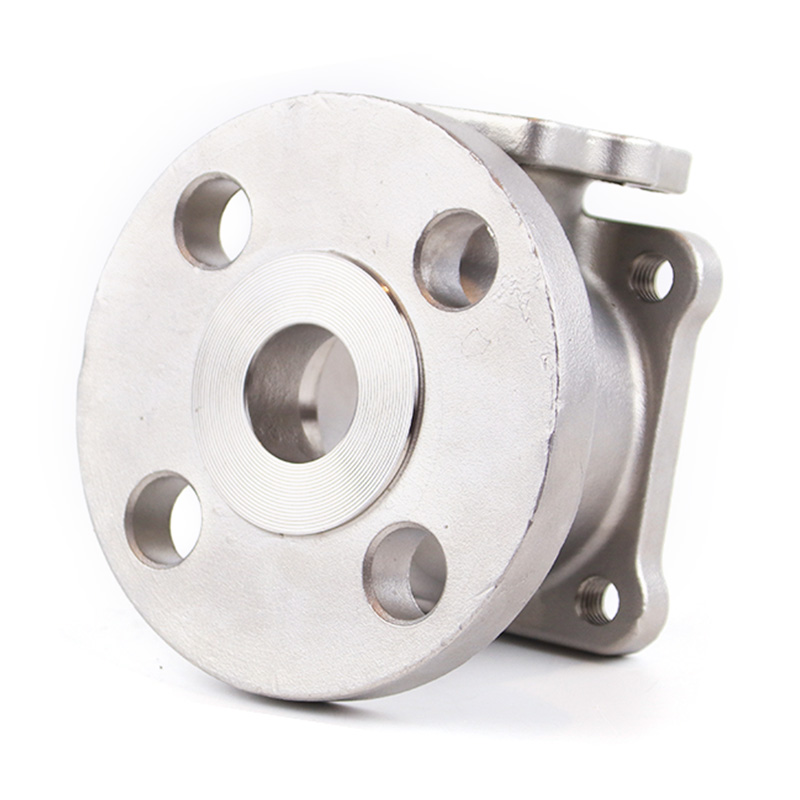

Flanged and Threaded Connections

The Working Pressure Ball Valve Casting is available in various connection types, including flanged and threaded. The flanged design allows for easy installation and maintenance, ensuring that the valve can be securely attached to a pipeline. Threaded options offer flexibility in systems where quick disassembly is required. The connection method used can be tailored to meet specific installation requirements, enhancing the adaptability of the Working Pressure Ball Valve Casting.

Application Diversity

The versatility of the Working Pressure Ball Valve Casting makes it suitable for various applications across multiple industries:

- Oil and Gas: In the oil and gas industry, these valves regulate the flow of crude oil, natural gas, and other hydrocarbons, ensuring safe and efficient operation in exploration and production processes.

- Chemical Processing: The Working Pressure Ball Valve Casting is essential in chemical plants, where it manages the flow of aggressive chemicals while maintaining safety standards.

- Water Treatment: In water treatment facilities, these valves help control the flow of water and treatment chemicals, playing a crucial role in maintaining water quality.

- Power Generation: The energy sector makes extensive use of the Working Pressure Ball Valve Casting to regulate steam and water flows in generation systems, ensuring optimized performance and safety.

- HVAC Systems: In heating, ventilation, and air conditioning systems, these valves control the flow of water or refrigerants, contributing to energy-efficient heating and cooling.

In conclusion,The Working Pressure Ball Valve Casting is a vital tool in fluid control applications across various industries. Its durable construction, high-performance sealing, and versatility under different working conditions make it a reliable choice in many operational settings.