Key Features

1. High-Quality Materials

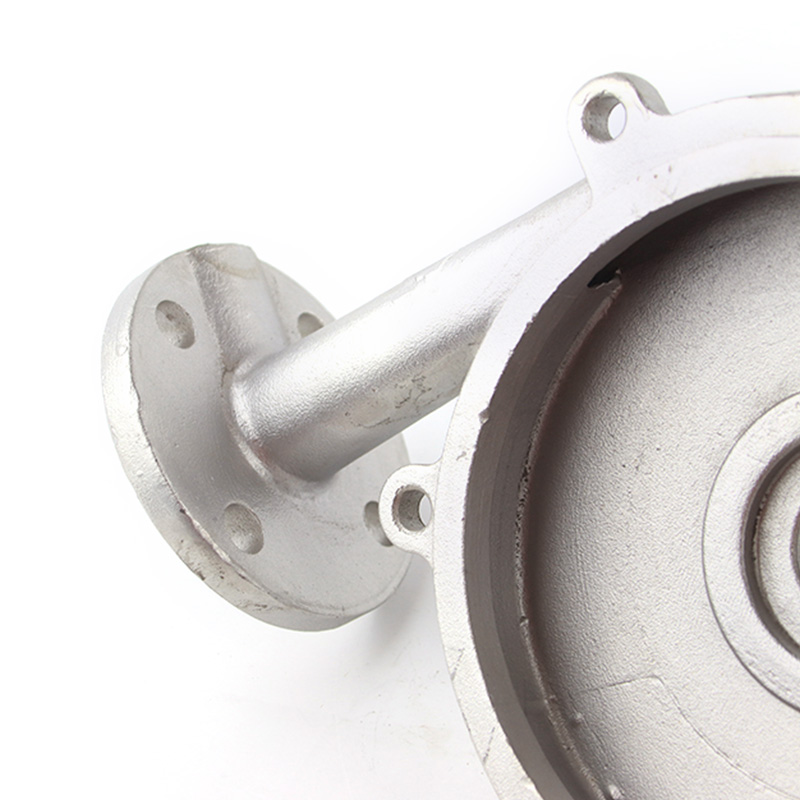

Precision Alloy Steel Pump Housing Casting is made from alloy steel, which is known for its outstanding mechanical properties. The use of alloy steel enhances the strength and toughness of the housing, making it suitable for high-stress applications. This material composition ensures that the housing can withstand the rigors of various operating conditions.

2. Precision Engineering

The manufacturing process of Precision Alloy Steel Pump Housing Casting employs good technology to ensure high dimensional accuracy. This precision engineering translates into good fitment for pump components, reducing the risk of leaks and operational inefficiencies. The precision in design contributes to the overall longevity of the pump system.

3. Corrosion and Wear Resistance

One of the major features of Precision Alloy Steel Pump Housing Casting is its resistance to corrosion and wear. The alloy composition not only strengthens the housing but also protects it against oxidative and chemical degradation. This characteristic makes it good choice for applications involving harsh fluids or extreme environmental conditions.

4.Efficient Heat Resistance

Precision Alloy Steel Pump Housing Casting is engineered to perform effectively under high-temperature scenarios. The thermal stability of alloy steel maintains the integrity of the housing, ensuring that it withstands thermal expansion and contraction without compromising performance. This feature is particularly important in applications where temperature fluctuations are common.

Advantages

1. Enhanced Durability

Precision Alloy Steel Pump Housing Casting offers exceptional durability, which is crucial for reduce continuous operation in industrial settings. The robust nature of alloy steel ensures that the housing can endure mechanical stresses and environmental factors without significant wear, reducing the need for frequent replacements.

2. Increased Efficienc

The precision fitment and quality construction of these pump housings contribute to increased operational efficiency. By minimizing leakage and ensuring good sealing, Precision Alloy Steel Pump Housing Casting helps maintain efficient fluid transfer and reduces energy consumption during pump operation.

3. Cost-Effective Solution

Investing in Precision Alloy Steel Pump Housing Casting can result in significant long-term savings. The durability and longevity of these housings reduce maintenance and replacement costs, offering a cost-effective solution for industries that rely on consistent performance from their pumping systems.

Applications

1. Water and Wastewater Treatment

Precision Alloy Steel Pump Housing Casting is widely used in water and wastewater treatment facilities. The corrosion-resistant properties of alloy steel make these housings ideal for environments where exposure to moisture and chemicals is prevalent.

2. Oil and Gas Industry

In the oil and gas sector, these pump housings provide the necessary strength and reliability to handle the extraction and transportation of crude oil and natural gas. Their durability allows them to perform under extreme pressures and temperatures commonly encountered in this industry.

3. Chemical Processing

The chemical processing industry benefits from Precision Alloy Steel Pump Housing Casting due to its ability to withstand aggressive chemicals. These pump housings are designed to safely contain chemicals while maintaining structural integrity.

In summary, Precision Alloy Steel Pump Housing Casting is an essential component for various industrial applications, offering a combination of strength, precision, and durability.