Key Features

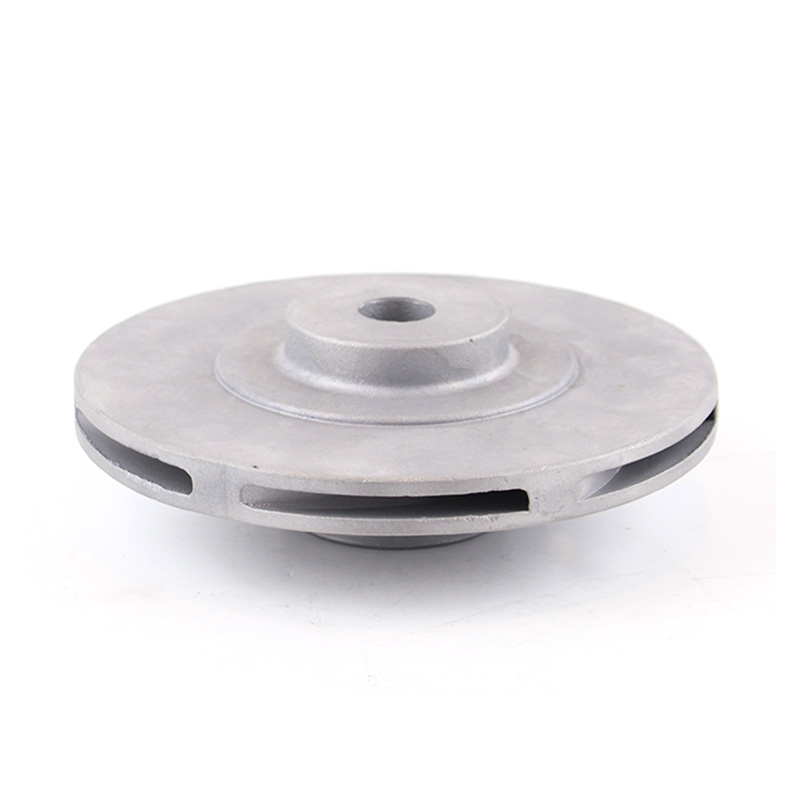

1. Precision Manufacturing: One of the good benefits of Investment Stainless Steel Casting for Pump Impeller is its precision. The investment casting process allows for the creation of complex geometries that are often difficult to achieve with traditional manufacturing methods. This precision is crucial because it ensures that the impellers fit nicely within their assemblies, optimizing pump performance.

2. Material Properties: The use of stainless steel in investment casting significantly improves the mechanical properties of the pump impellers. Stainless steel provides high tensile strength, good corrosion resistance, and durability, which are essential for pumps operating in challenging environments such as chemical processing, water treatment, and oil and gas industries.

3. Surface Finish: Investment Stainless Steel Casting for Pump Impeller results in a smooth surface finish with minimal post-processing required. This characteristic is essential because a smooth surface reduces turbulence and wear within the pump, enhancing overall efficiency and performance.

4. Design Flexibility: The investment casting process offers considerable design flexibility. Engineers can create intricate and lightweight designs that would be impractical with other manufacturing methods. This capability allows for the optimization of the pump impeller's hydrodynamic performance, leading to improved efficiency and effectiveness.

5. High Production Efficiency: The investment casting process is efficient for producing both small and large quantities of pump impellers. Once the initial molds are created, the production process can be streamlined to produce consistent and reliable parts quickly, meeting the demands of varying project timelines.

6. Resistance to Corrosion: Stainless steel inherently resists oxidation and corrosion, which is particularly important in applications involving liquids that may be corrosive or abrasive. Investment Stainless Steel Casting for Pump Impeller helps ensure that the impellers maintain their integrity and function over time, which reduces maintenance costs and prolongs service life.

Applications

1. Water and Wastewater Management: Pump impellers used in municipal and industrial water systems benefit from corrosion resistance and reliability, ensuring effective fluid transport.

2. Chemical Processing: In the chemical industry, impellers must withstand aggressive substances. Investment stainless steel casting provides the necessary resistance against corrosion and wear.

3. Oil and Gas: The exploration and production of oil and gas require durable equipment that can handle harsh conditions. The investment casting process ensures the integrity and efficiency of pump impellers used in this sector.

4. Food Processing: Compliance with hygiene standards is crucial in food applications. Investment Stainless Steel Casting for Pump Impeller meets stringent sanitary requirements while providing robust performance.

5. Power Generation: Impellers play a critical role in cooling systems within power plants. The durability and efficiency achieved through investment casting enhance the reliability of these systems.

In conclusion,Investment Stainless Steel Casting for Pump Impeller stands out as a reliable and effective solution for various pumping applications. The combination of precision manufacturing, good material properties, and design flexibility allows for the production of high-quality impellers that meet the demands of diverse industries.