High Precision Manufacturing

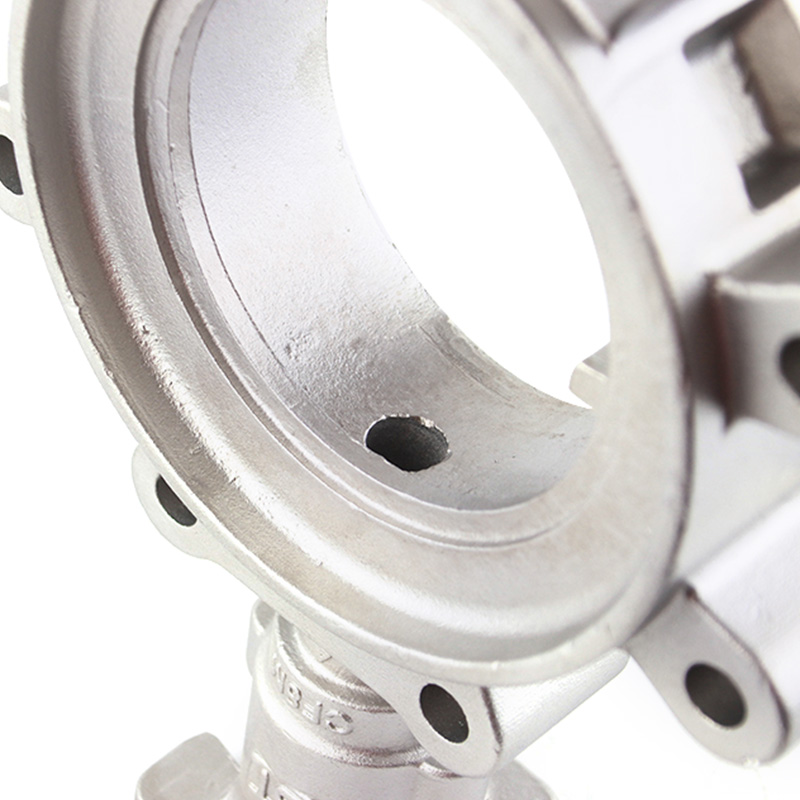

The Precision Casting Butterfly Valve Body is crafted using good precision casting methods. This process allows for intricate designs and tight tolerances, ensuring that each valve body adheres to industry standards. With precise dimensions, the butterfly valve body guarantees a tight seal and good flow control, reduce the risk of leaks and maintenance issues.

Durable Materials

Constructed from high-quality materials, the Precision Casting Butterfly Valve Body exhibits good resistance to wear and corrosion. Common materials used in the manufacturing process include stainless steel, carbon steel, and various alloy compositions. These materials not only enhance the valve body’s durability but also extend its lifespan, making it a cost-effective solution for industrial operations.

Efficient Flow Control

The design of the Precision Casting Butterfly Valve Body allows for efficient flow regulation. The disc, which is positioned in the center of the valve body, rotates to open or close the flow. This design pressure drops and ensures smooth operation, making it good for both throttling and on/off applications in various pipelines.

Versatile Applications

The Precision Casting Butterfly Valve Body is suitable for a wide range of applications across various industries. It can be employed in water treatment plants, chemical processing facilities, HVAC systems, and power generation plants. Its versatility makes it an integral part of many systems requiring reliable flow control solutions.

Ease of Installation and Maintenance

Designed for user-friendly installation, the Precision Casting Butterfly Valve Body simplifies the integration process within existing systems. Its compact structure facilitates easy handling and mounting. Furthermore, the low maintenance requirements of this valve body contribute to reduced downtime, enhancing overall operational efficiency.

Cost-Effective Production

Precision casting significantly lowers production costs by reduce material waste and enabling mass production of complex parts. This economic efficiency makes the Precision Casting Butterfly Valve Body an attractive option for businesses seeking quality components without overspending.

Enhanced Mechanical Properties

The precision casting process enhances the mechanical properties of the valve body. This ensures that the Butterfly Valve Body can withstand high pressures and extreme temperatures, making it suitable for challenging operating conditions. The robust nature of the casting also contributes to its reliability in critical applications.

Consistent Quality

With stringent quality control measures in place, the Precision Casting Butterfly Valve Body consistently meets the required specifications. This commitment to quality results in higher performance and longevity of the valve, reducing the need for replacements and repairs over time.

In summary, the Precision Casting Butterfly Valve Body stands out due to its high precision manufacturing processes, durability, and versatile applications. Its ability to control fluid flow efficiently, combined with ease of installation and maintenance, makes it a good choice in various industrial settings. As industries continue to seek reliable solutions for flow control, the Precision Casting Butterfly Valve Body remains a formidable option, ensuring that operational efficiency and safety standards are upheld.