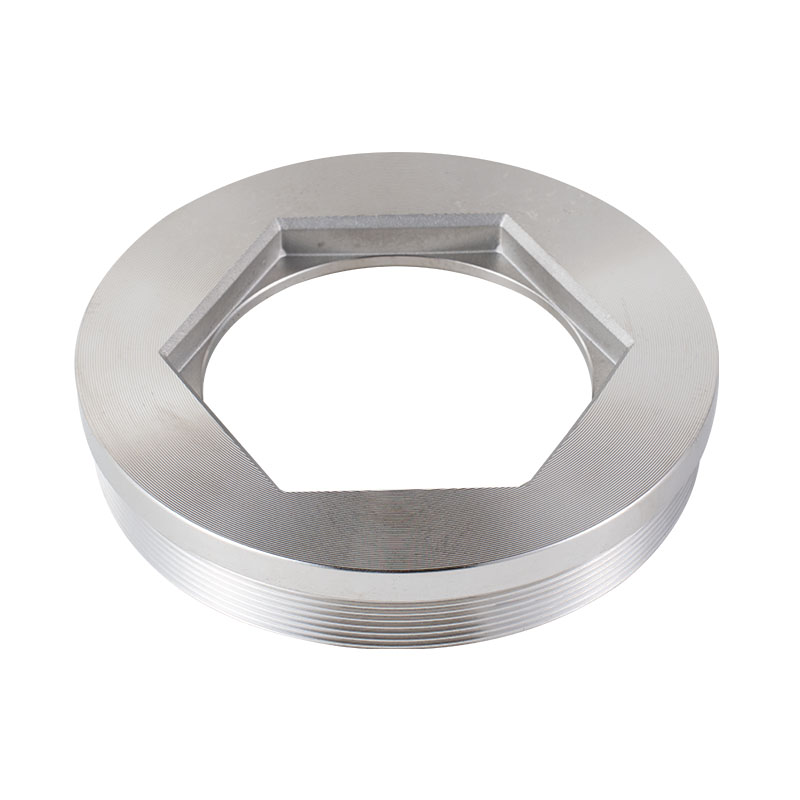

Precision Engineering

One of the key advantages of Stainless Steel Precision Ball Valve Casting Parts is their precision engineering. These parts are crafted with meticulous attention to detail, ensuring that every component fits together seamlessly to provide smooth, leak-free operation. The precision of these casting parts is crucial in applications where fluid control is critical, such as in pharmaceutical manufacturing, food processing, and chemical production. By minimizing the risk of contamination and ensuring consistent flow rates, Stainless Steel Precision Ball Valve Casting Parts contribute significantly to the quality and safety of the final product.

Corrosion Resistance

Stainless Steel Precision Ball Valve Casting Parts are renowned for their good corrosion resistance, a property that makes them suit for use in harsh environments. Whether exposed to aggressive chemicals, high temperatures, or corrosive substances, these casting parts maintain their integrity and performance. This characteristic is particularly valuable in marine applications, oil and gas operations, and wastewater treatment facilities, where the risk of corrosion can compromise system reliability and safety. By withstanding such conditions, Stainless Steel Precision Ball Valve Casting Parts reduce the need for frequent replacements and maintenance, thereby lowering operational costs.

High-Performance Sealing

The sealing mechanism of Stainless Steel Precision Ball Valve Casting Parts is designed to provide high-performance sealing under various pressure conditions. This ensures that fluid flow is precisely controlled, with minimal risk of leaks or spills. The reliability of the sealing system is critical in applications where safety and environmental protection are important, such as in chemical processing and power generation. By preventing fluid loss and maintaining system integrity, Stainless Steel Precision Ball Valve Casting Parts play a vital role in safeguarding both personnel and the environment.

Cost-Effectiveness

While the initial investment in Stainless Steel Precision Ball Valve Casting Parts may be higher than that of less durable alternatives, their cost-effectiveness becomes apparent over time. The reduced need for maintenance, repairs, and replacements, combined with the enhanced operational efficiency they provide, makes Stainless Steel Precision Ball Valve Casting Parts a financially sound choice for businesses. By reduce downtime and optimizing system performance, these casting parts contribute to increased productivity and reduced operational costs, premierly enhancing profitability.

Applications Across Diverse Industries

- Food Processing: The use of Stainless Steel Precision Ball Valve Casting Parts in food processing ensures cleanliness and prevents contamination, safeguarding consumer health.

- Chemical Manufacturing: These parts are essential in chemical plants for handling corrosive substances, providing a reliable and safe means of fluid control.

- Oil and Gas: In the oil and gas sector, Stainless Steel Precision Ball Valve Casting Parts are used for controlling the flow of hydrocarbons, contributing to operational safety and efficiency.

- Power Generation: The reliability and performance of these casting parts make them critical in power plants, where they manage steam and water flow to ensure efficient energy production.

In conclusion, Stainless Steel Precision Ball Valve Casting Parts are a cornerstone of modern fluid control systems, offering unparalleled precision, reliability, and performance.