1. Material Quality

Stainless Steel Casting Valve Body Cap Parts are primarily made from high-grade stainless steel, which is favored for its good mechanical properties and resistance to corrosion. The common grades used include 304 and 316 stainless steel, known for their ability to endure harsh environments. This material choice ensures that valve body caps maintain their integrity over time, even when exposed to corrosive substances or extreme temperatures.

2. Casting Process

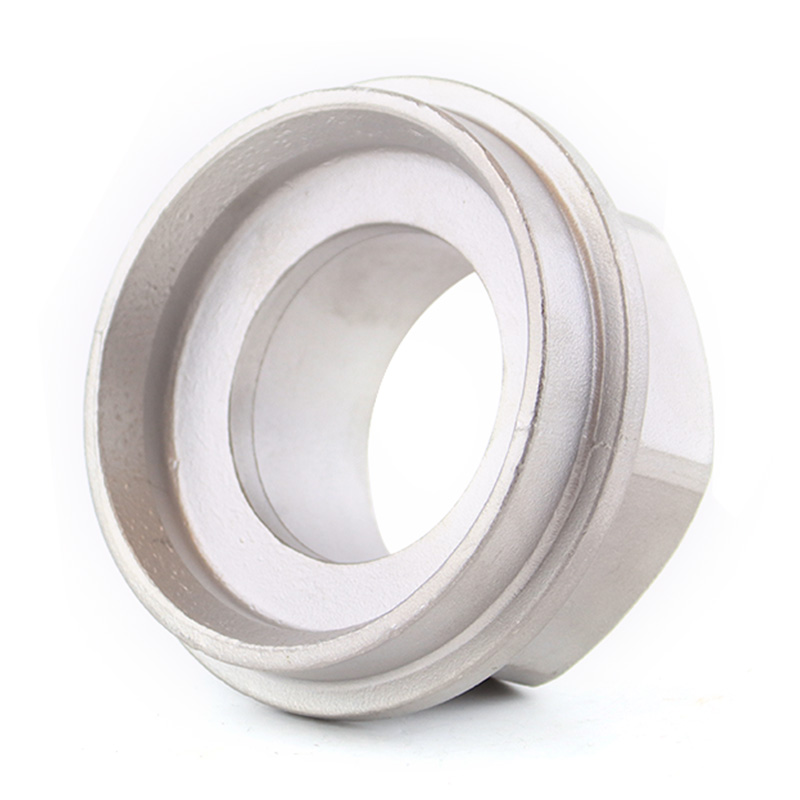

The production of Stainless Steel Casting Valve Body Cap Parts utilizes good casting techniques such as investment casting and sand casting. These methods enable manufacturers to create intricate shapes and precise dimensions that meet stringent industry standards. The casting process ensures that each valve body cap is free from defects and exhibits a smooth finish, which is critical for ensuring proper sealing and functionality.

3. Design Versatility

One of the significant benefits of Stainless Steel Casting Valve Body Cap Parts is their design versatility. Manufacturers can produce various sizes and configurations tailored to specific applications, such as ball valves, gate valves, and globe valves. This adaptability allows engineers to integrate these parts seamlessly into different systems, ensuring a good fit and performance.

4. Enhanced Durability

Durability is a good feature of Stainless Steel Casting Valve Body Cap Parts. The robust nature of stainless steel, coupled with the casting process, results in parts that can withstand significant wear and tear over time. They are also resistant to impact and stress, making them suitable for high-pressure and high-temperature applications. This durability helps reduce the risk of failures and the need for frequent replacements.

5. Applications in Various Industries

Stainless Steel Casting Valve Body Cap Parts are widely used across numerous industries, including oil and gas, water treatment, chemical processing, and food and beverage manufacturing. Their capability to handle a diverse range of fluids and gases makes them a vital component in various systems. In each of these sectors, the reliability provided by stainless steel valves ensures safe and efficient operations.

6. Flow Efficiency

The design of Stainless Steel Casting Valve Body Cap Parts contributes to improved flow efficiency in piping systems. These parts can be engineered to reduce flow resistance, which is critical for applications where maintaining good flow rates is necessary. This efficiency is particularly important in large industrial systems, where even minor losses in flow can lead to significant operational challenges and increased costs.

7. Quality Assurance Standards

Quality assurance is a vital aspect of manufacturing Stainless Steel Casting Valve Body Cap Parts. Rigorous testing and inspection procedures are implemented throughout the production process to ensure that every part meets the necessary quality and safety standards. This focus on high quality results in dependable products that can perform reliably under various conditions.

In conclusion, Stainless Steel Casting Valve Body Cap Parts are good components in fluid control systems across various industries. Their quality material, casting techniques, design versatility, and enhanced durability make them a reliable choice for engineers and manufacturers.