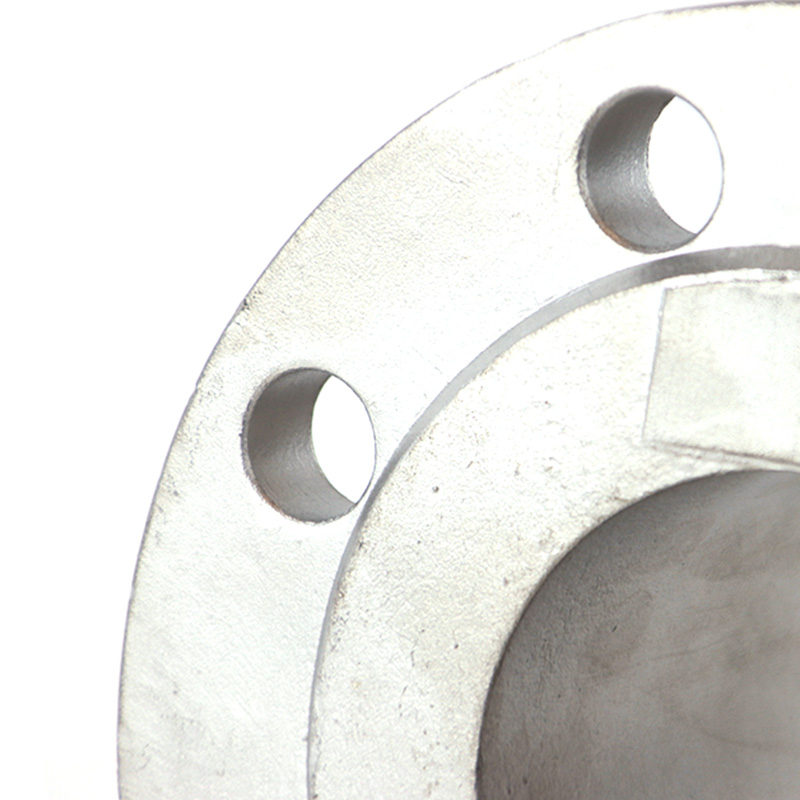

Material and Construction

Precision Stainless Steel Ball Valve Castings are engineered with high-quality stainless steel, a material renowned for its good corrosion resistance, durability, and mechanical strength. This choice of material ensures that the castings can withstand a wide range of operating conditions, including exposure to aggressive chemicals, fluctuating temperatures, and high pressures. The stainless steel composition also provides a smooth surface finish, reducing the risk of contamination and ensuring reliable performance in critical applications.

Precision Engineering

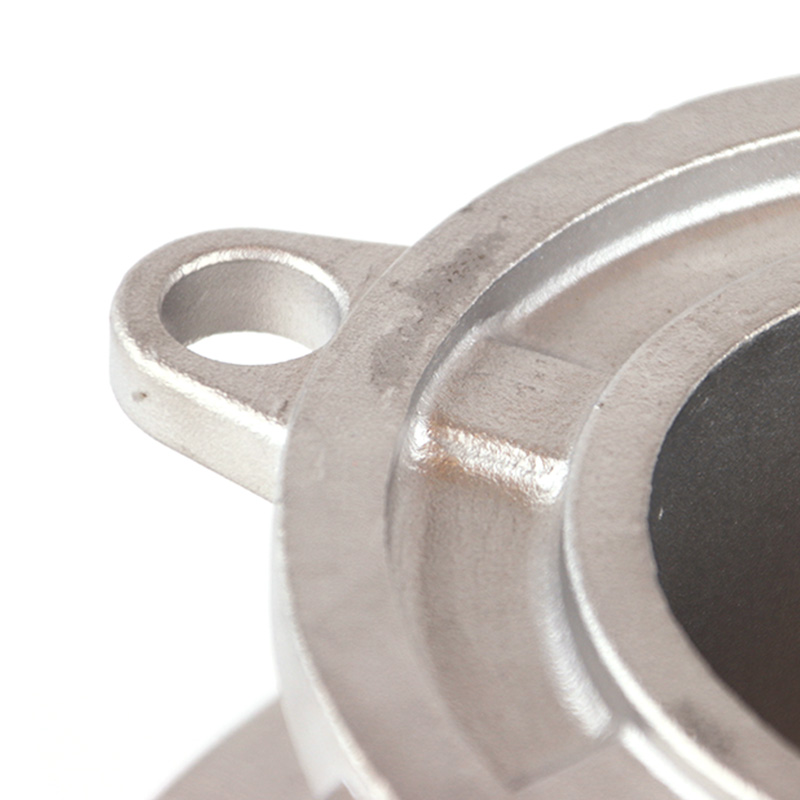

The manufacturing process of Precision Stainless Steel Ball Valve Castings involves good precision casting techniques. These methods allow for the production of components with extremely tight tolerances, ensuring a nice fit and good functionality. Each casting is carefully designed and machined to meet specific customer requirements, resulting in a high level of consistency and reliability. The precision engineering ensures that the ball valve castings operate smoothly, with minimal wear and tear over time.

Versatility in Applications

One of the key strengths of Precision Stainless Steel Ball Valve Castings is their versatility. These castings are suitable for a wide range of industries, including oil and gas, chemical processing, pharmaceuticals, food and beverage, and water treatment. Their ability to handle various types of fluids, from highly corrosive acids to clean water, makes them a good choice for diverse industrial applications. Additionally, the castings can be customized to meet specific pressure and temperature requirements, further enhancing their adaptability.

Enhanced Durability and Longevity

Precision Stainless Steel Ball Valve Castings are designed to provide long-term reliability and less maintenance. The use of stainless steel ensures that the castings are resistant to rust, corrosion, and wear, even in harsh environments. This durability not only reduces the need for frequent replacements but also reduce downtime and maintenance costs for industrial operations. The robust construction of these castings ensures that they can withstand repeated cycles of operation without compromising performance.

Tight Sealing and Leak Prevention

A critical feature of Precision Stainless Steel Ball Valve Castings is their ability to provide a tight seal, preventing leaks and ensuring precise flow control. The precision casting process ensures that the ball valve components fit together seamlessly, reduce the risk of fluid leakage. This tight sealing capability is essential in applications where fluid containment and safety are important, such as in chemical processing plants or pharmaceutical manufacturing facilities.

Environmental and Safety Compliance

In addition to their performance benefits, Precision Stainless Steel Ball Valve Castings are designed with environmental and safety considerations in mind. The stainless steel material is recyclable and does not leach harmful substances into the environment. Moreover, the tight sealing and leak prevention capabilities of these castings help to reduce the risk of hazardous fluid spills, ensuring compliance with environmental regulations and safety standards.

In conclusion,the Precision Stainless Steel Ball Valve Castings represent a reliable, durable, and versatile solution for industrial flow control applications.