Key Features

Precision Casting Process

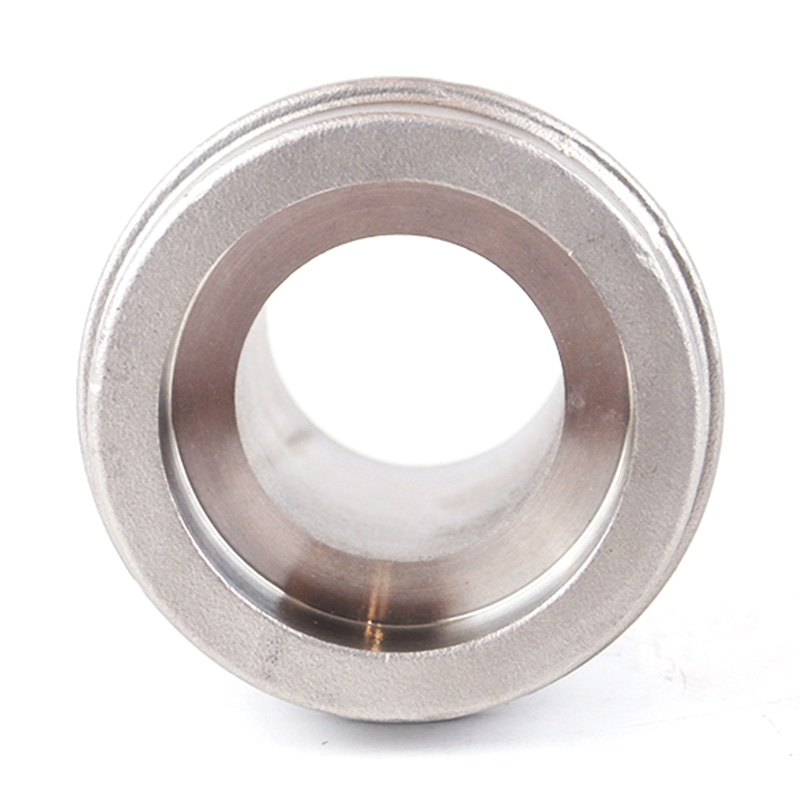

The High Precision Stainless Steel Ball Valves Casting utilizes good investment casting techniques, often referred to as the lost-wax process. This method involves creating a wax pattern of the valve, coating it with a ceramic shell, and then melting out the wax to create a mold. The molten stainless steel is then poured into the mold, resulting in intricate and precise components with good surface finishes. This process ensures that the valves meet tight tolerance requirements, particularly for critical components like seats and sealing surfaces.

Material Quality

The valves are manufactured using high-quality 304 stainless steel, known for its good corrosion resistance, mechanical strength, and durability. This material choice ensures that the valves can withstand harsh operating conditions, such as exposure to corrosive fluids and high pressures. Additionally, the use of 304 stainless steel provides a longer service life and reduced maintenance requirements.

Defect-Free Casting

One of the primary advantages of the High Precision Stainless Steel Ball Valves Casting is its ability to produce defect-free components. Through optimized casting processes, common defects such as shrinkage porosity, cavities, and cold shuts are reduce or eliminated. This is achieved through precise control of the casting parameters, including pouring temperature, speed, and mold preheating. For example, an optimized investment casting process for 304 stainless steel ball valves has been shown to significantly reduce shrinkage porosity rates, ensuring structural integrity and performance.

Applications

Industrial Fluid Control

The High Precision Stainless Steel Ball Valves Casting is widely used in industrial fluid control systems, where precise flow control and reliability are essential. These valves are commonly found in petrochemical plants, power generation facilities, and water treatment plants. Their corrosion-resistant properties make them suit for handling aggressive chemicals and high-pressure steam.

Marine and Offshore Industries

In marine and offshore applications, the valves must withstand harsh environmental conditions, including saltwater exposure and high mechanical stress. The High Precision Stainless Steel Ball Valves Casting ensures that these valves meet the stringent requirements of these industries, providing long-term durability and less maintenance.

Aerospace and Defense

For aerospace and defense applications, where precision and reliability are critical, the High Precision Stainless Steel Ball Valves Casting offers the high-quality components needed to ensure system integrity. These valves are used in fuel systems, hydraulic controls, and other critical applications where failure is not an option.

In conclusion,the High Precision Stainless Steel Ball Valves Casting represents a significant good in valve manufacturing, offering good precision, durability, and reliability. By leveraging good investment casting techniques and high-quality materials, these valves meet the stringent requirements of various industrial applications. Whether used in petrochemical plants, marine environments, or aerospace systems, the High Precision Stainless Steel Ball Valves Casting provides a robust and long-lasting solution for fluid control.