Cryogenic Valve Casting has gained increasing importance in modern industries that require equipment capable of handling extremely low temperatures. From liquefied natural gas (LNG) to liquid hydrogen and industrial gas storage, valves designed for cryogenic conditions must combine durability, precision, and reliability. Casting technology has played a central role in producing components that meet these challenges, offering manufacturers a way to ensure quality while meeting rising global demand.

One of the defining features of cryogenic valve casting is the careful selection of materials. At very low temperatures, many metals become brittle and lose their mechanical strength. To address this, stainless steel and nickel-based alloys are widely used because they maintain toughness and resistance to fracture under extreme cold. For example, austenitic stainless steel retains ductility even at temperatures below -196°C, making it a common choice for cryogenic service.

Nickel alloys provide additional advantages, including enhanced resistance to corrosion and oxidation. These characteristics are particularly important when valves are exposed to liquefied gases that could otherwise weaken the material over time. The ability to choose materials based on performance in cryogenic environments ensures that valve discs and bodies can operate safely and consistently in demanding conditions.

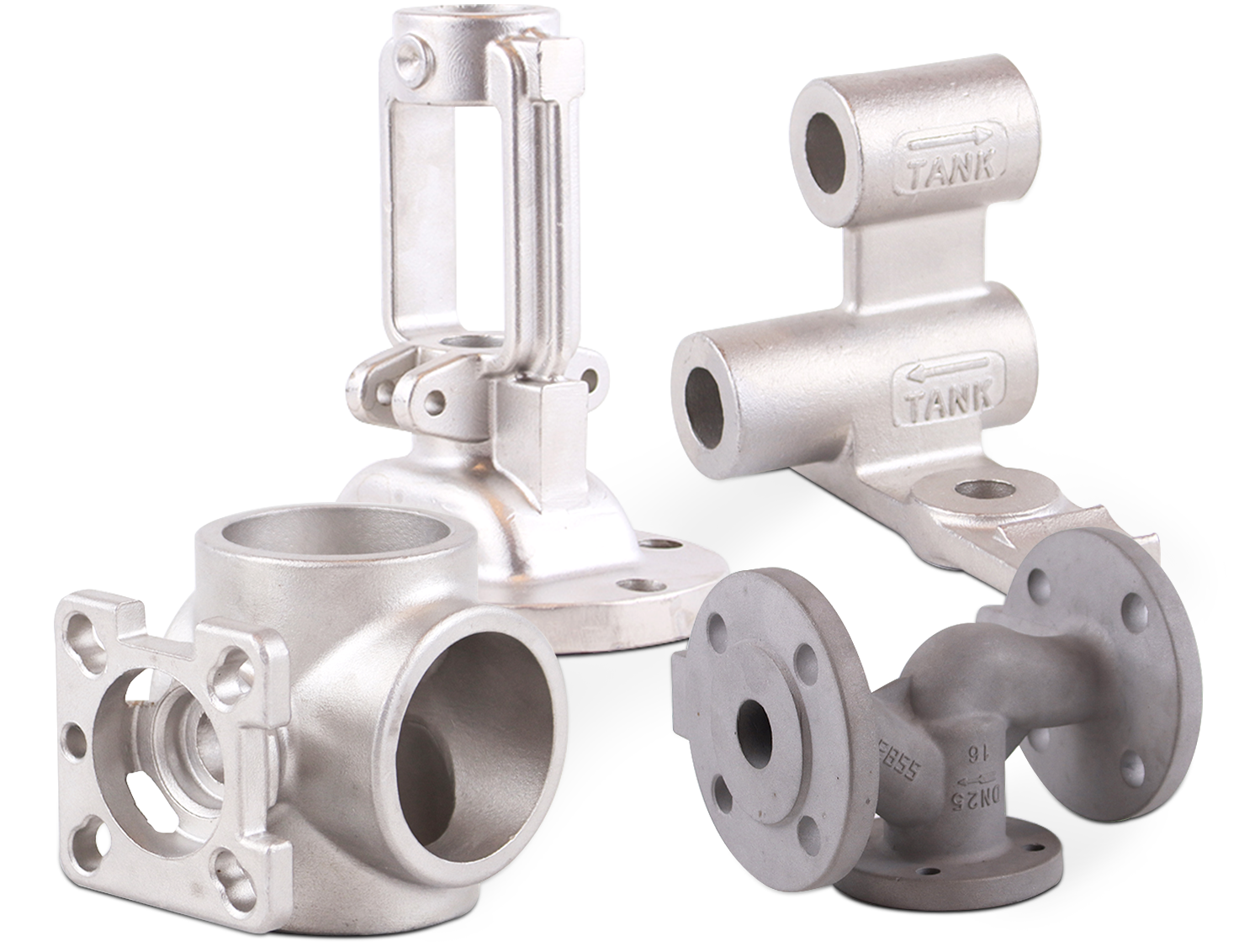

Manufacturers of cryogenic valves have increasingly focused on refining their casting methods. Investment casting, often referred to as precision casting, has become a preferred technique for producing components with complex geometries and fine surface finishes. This method minimizes machining requirements and ensures a uniform structure, which is critical for performance under cryogenic stress.

Vacuum casting is also applied in situations where controlling impurities and porosity is essential. Sand casting continues to be used for larger parts, although advanced monitoring techniques are now applied to improve dimensional accuracy and surface quality. These casting methods, combined with rigorous inspection processes, ensure that cryogenic valves meet international standards for safety and reliability.

The application of cryogenic valve casting extends across several industries. In the energy sector, LNG plants rely heavily on valves capable of operating in storage tanks, transfer lines, and processing facilities.

Market trends indicate a steady rise in demand for cryogenic valves, particularly in regions investing heavily in energy transition projects. Manufacturers are responding by expanding production capacity, adopting advanced casting processes, and developing alloys tailored for these applications. This combination of industrial need and technological advancement is shaping the future of cryogenic valve casting.

Another important aspect of cryogenic valve casting is quality assurance. Foundries implement non-destructive testing, pressure tests, and dimensional inspections to ensure every component meets strict criteria. This focus on quality reduces the risk of leakage, mechanical failure, or costly downtime in critical operations.

Sustainability is also becoming part of the discussion. By reusing casting molds, recycling scrap metals, and reducing energy consumption during production, manufacturers are aligning with global initiatives to lower environmental impact. These efforts not only support long-term industry growth but also reflect responsible manufacturing practices.

The development of cryogenic valve casting highlights how materials science, advanced manufacturing, and market demand intersect to create reliable industrial solutions. For product inquiries or more information, please contact Baoli Company.